Precision Heat Treatment: Enhancing Strength, Durability, and Performance in Manufacturing

Precision Heat Treatment: Enhancing Strength, Durability, and Performance in Manufacturing

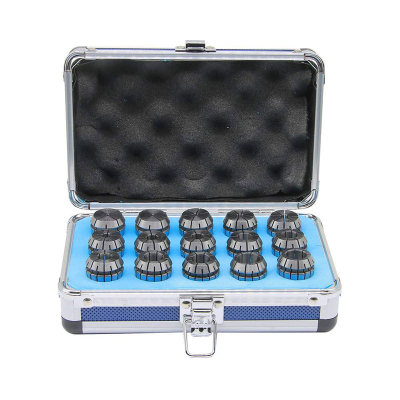

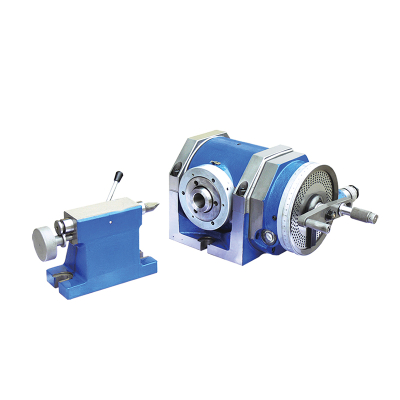

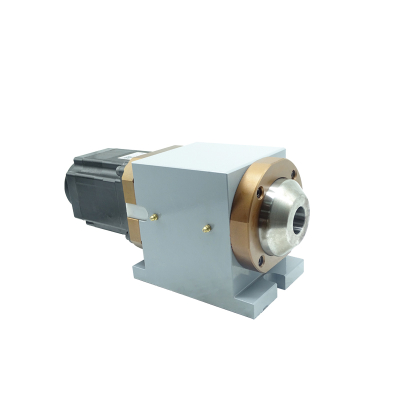

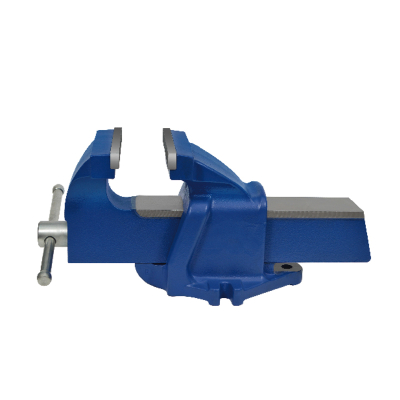

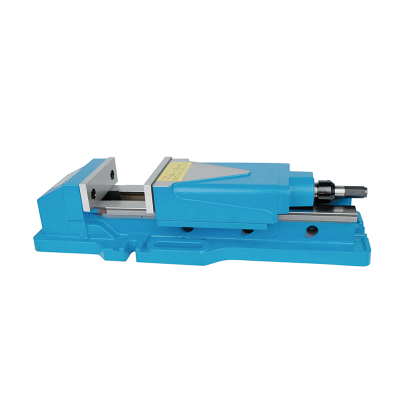

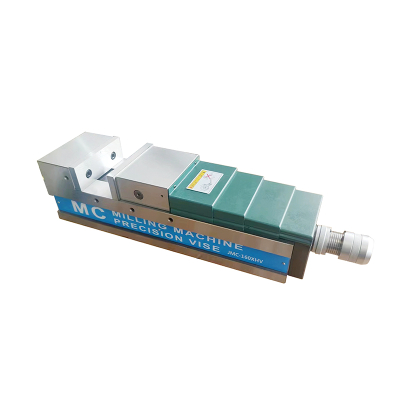

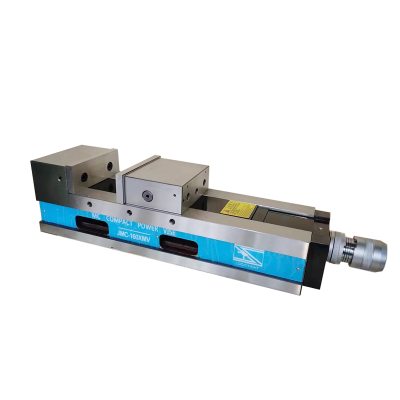

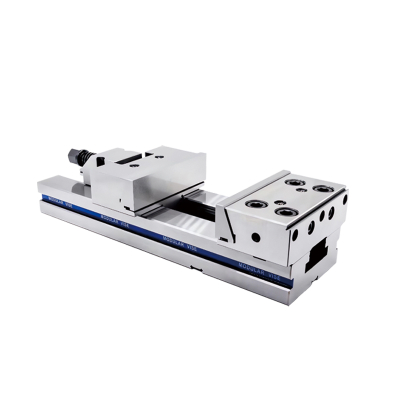

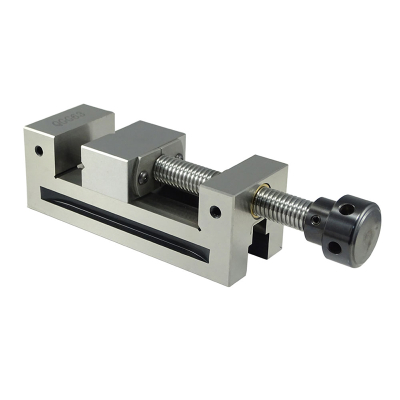

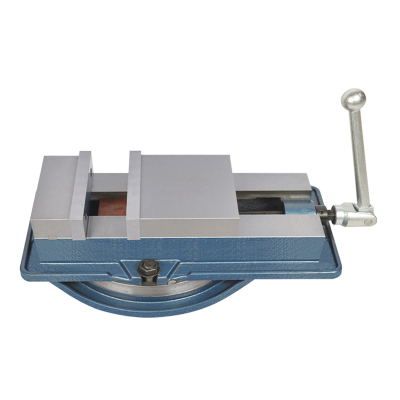

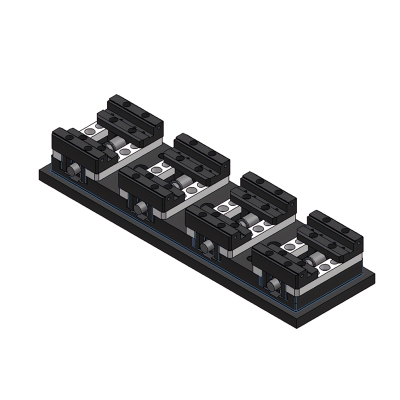

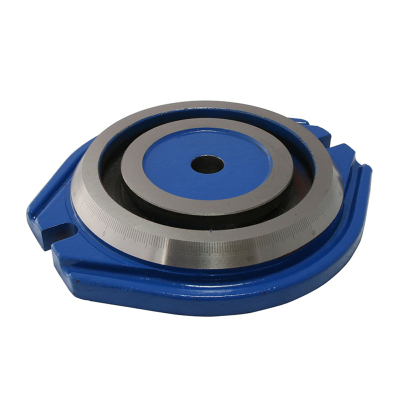

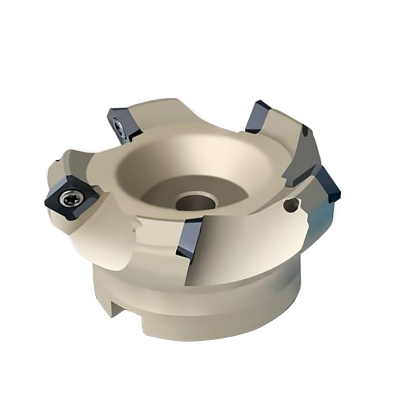

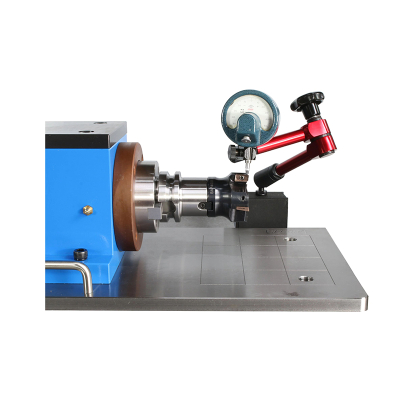

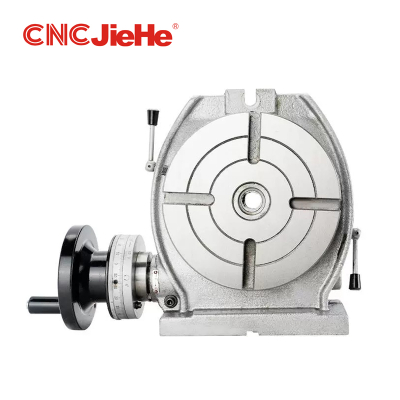

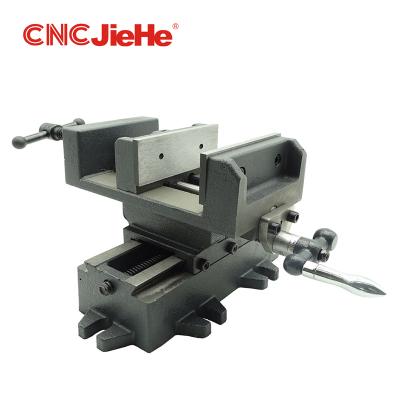

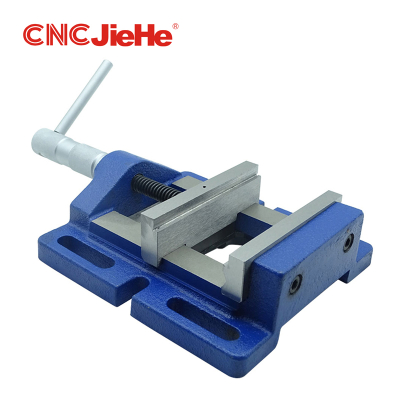

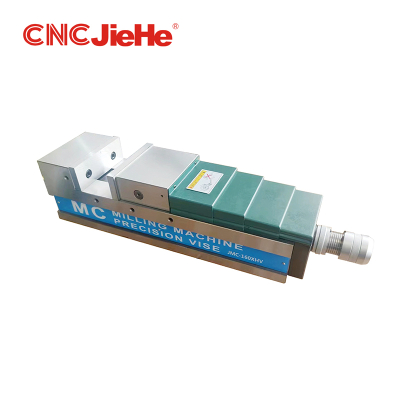

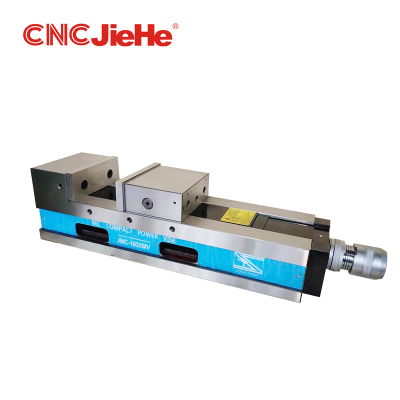

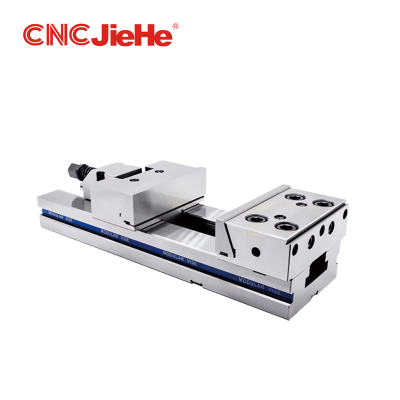

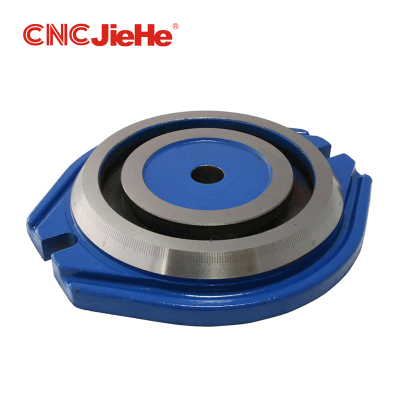

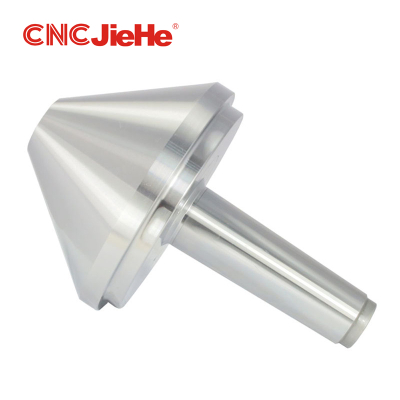

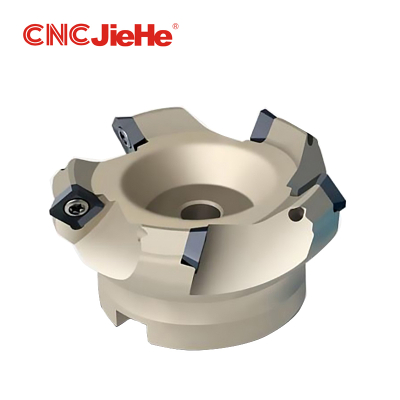

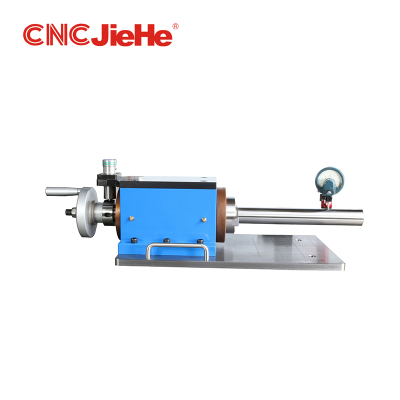

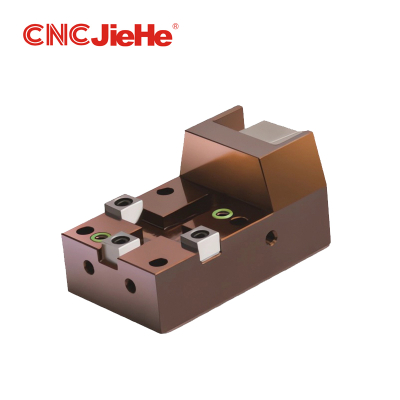

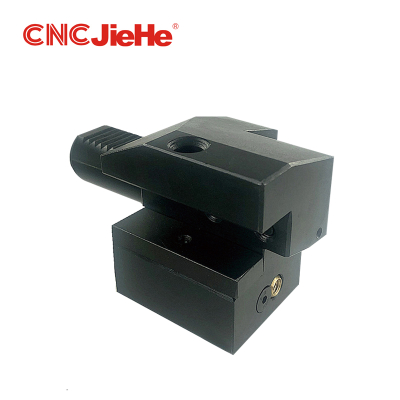

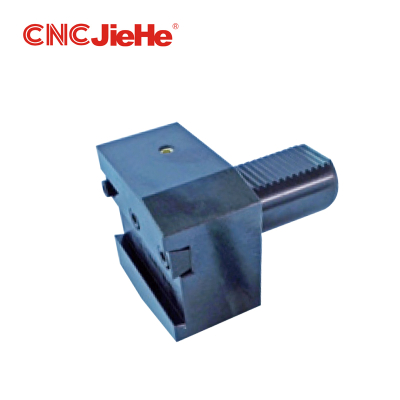

Heat treatment is a key process in materials science and engineering, including controlled heating and cooling of materials to improve their mechanical properties, durability and other physical properties. A heat treatment workshop is a facility where metal materials undergo heat treatment processes, typically applied to mechanical components, molds, and other parts. Common methods include quenching, tempering, and normalizing. To ensure product precision, all products from Jiehe Company undergo heat treatment processes, guaranteeing stable product quality. Through precise heat treatment techniques, the hardness, strength, wear resistance, and toughness of products are improved. Below are the core advantages of heat treatment:

1. Enhancing Material Strength and Hardness

Heat treatment significantly improves the strength and hardness of metallic materials, making them more suitable for high stress or high wear environment. For example, quenching and tempering processes can enhance the hardness and toughness of steel.

2. Improving Wear Resistance and Durability

Heat treatment increases the surface hardness and wear resistance of materials, thus prolonging its service life. For instance, surface hardening treatments such as carburizing and nitriding can enhance the wear resistance of component surfaces.

3. Increasing Material Toughness

Heat treatment (e.g., tempering) balances the hardness and toughness of materials, preventing brittle fractures under impact. This is particularly important for components subjected to dynamic loads.

4. Relieving Internal Stresses

During the manufacturing process, residual stresses may be generated inside the materials, resulting in deformation or cracking.Heat treatment (e.g., annealing or normalizing) effectively eliminates these internal stresses, improving dimensional stability and reliability.

5. Optimizing Microstructure

Heat treatment refines the grain structure of materials and makes it more uniform and compact, thus improving the overall performance of the material. For example, normalizing can refine grains and improve the comprehensive mechanical properties of materials.

6. Enhancing Corrosion Resistance

Certain heat treatment processes (e.g., nitriding) can form corrosion-resistant compounds on the material surface, improving its resistance to corrosion in harsh environments.

The core advantages of heat treatment is that it can significantly improve the mechanical properties, durability and processability of materials, eliminate internal stresses and optimizing microstructure at the same time. Through customized heat treatment processes, it meets the needs of various industries and applications, making it an indispensable technology in modern manufacturing.